Conceptual Design & Master Planning

Transform your business vision into a bankable facility concept with our data-driven approach to project definition and master planning. We align stakeholders, validate feasibility, and create phased development roadmaps that support long-term growth while managing capital investment risk.

Foundation for Success

Successful meat and dairy processing facilities begin with thorough planning and stakeholder alignment. IMP's conceptual design services establish clear project parameters, validate technical and economic feasibility, and create a roadmap for implementation that minimizes risk and maximizes return on investment.

Our approach combines operational expertise with engineering rigor to develop practical, capital-efficient solutions. We've developed conceptual designs for facilities ranging from small specialty operations to large-scale industrial complexes, always focusing on solutions that are buildable, operable, and profitable.

Whether you're optimizing existing processes, evaluating expansion options, or planning a greenfield development, our conceptual design process provides the documented due diligence needed to secure funding and move forward with confidence.

Our Conceptual Design Process

Requirements Definition

Establish project objectives, capacity requirements, product mix, and success criteria through stakeholder workshops and market analysis.

Technical Development

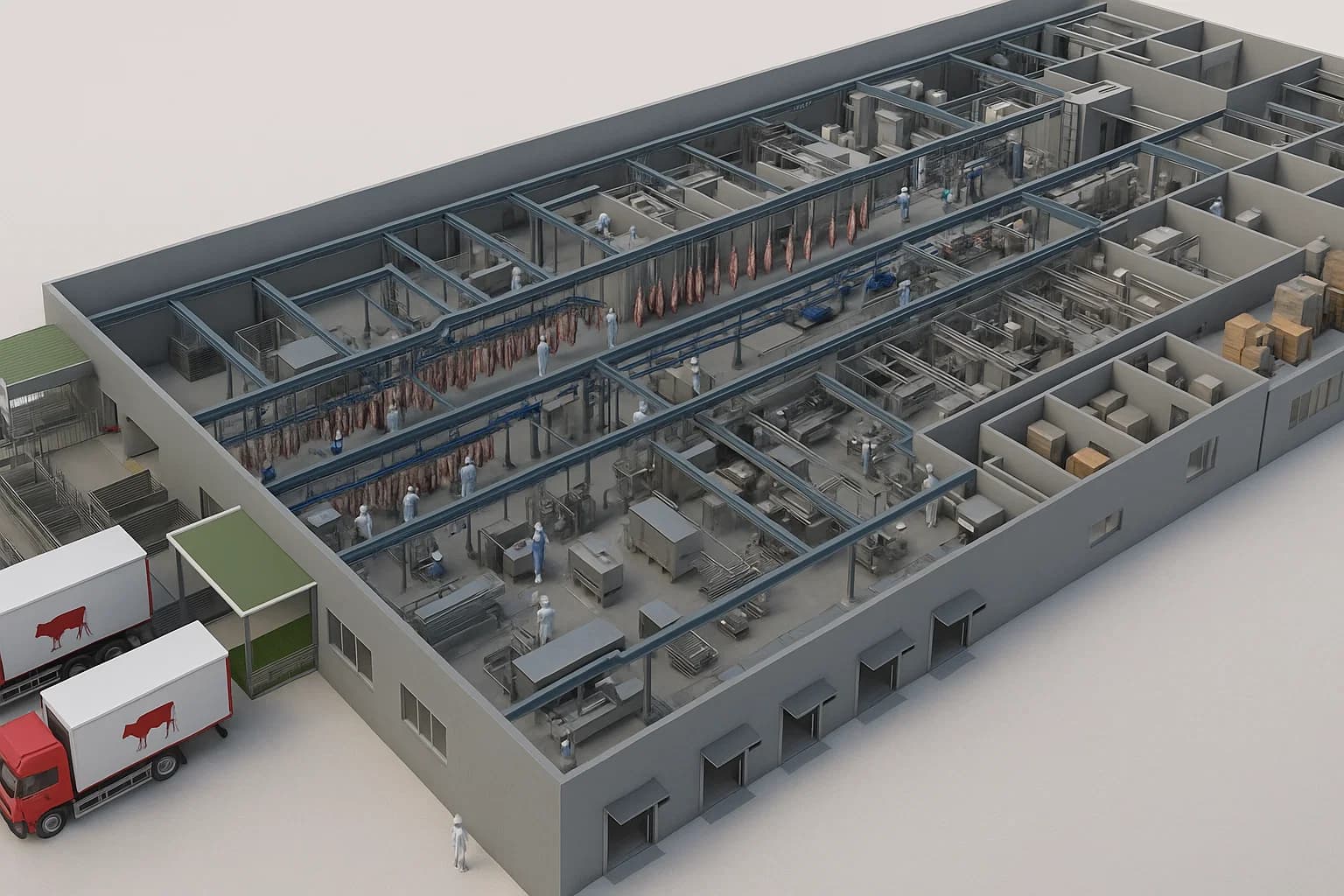

Create process flow diagrams, mass balances, equipment specifications, and facility layouts optimized for efficiency and future flexibility.

Financial Analysis

Develop detailed capital estimates, operating cost projections, and return on investment calculations to validate business case.

Implementation Planning

Create phased development plans, project schedules, and risk mitigation strategies to ensure successful execution.

Project Definition Report

Our comprehensive Project Definition Report provides the documented analysis and planning needed to make informed investment decisions and secure project funding. Each report is customized to your specific requirements but typically includes:

Technical Documentation

Detailed engineering analysis establishing the technical foundation for your project.

- •Process flow diagrams showing product movement through facility

- •Mass balance calculations for all major processes

- •Preliminary equipment lists with capacity specifications

- •Utility consumption estimates and infrastructure requirements

- •Conceptual facility layouts optimized for flow and expansion

- •Site development plans including utilities and logistics

Financial Analysis

Comprehensive cost estimates and financial projections to validate investment decisions.

- •Detailed capital cost estimates (+/- 20% accuracy)

- •Operating cost projections including labor, utilities, and maintenance

- •Revenue projections based on product mix and market analysis

- •Return on investment and payback period calculations

- •Sensitivity analysis for key variables

- •Funding requirements and cash flow projections

Implementation Strategy

Clear roadmap for moving from concept to operational facility with minimized risk.

- •Project milestone schedule with critical path identification

- •Phased development options to manage capital deployment

- •Risk assessment with mitigation strategies

- •Regulatory compliance requirements and timeline

- •Procurement strategy for major equipment and systems

- •Organizational requirements for construction and operations

Master Planning Services

Prepare for long-term success with master plans that accommodate growth, technology evolution, and market changes over 5, 10, or 15-year horizons. Our master planning services help you make smart investments today that support tomorrow's opportunities.

Greenfield Master Plans

Develop new sites with infrastructure and layout designed for phased expansion:

- • Phase 1 core facility with future expansion zones

- • Utility infrastructure sized for ultimate capacity

- • Site circulation planning for increased traffic

- • Flexible building designs for process changes

- • Environmental permits covering full buildout

- • Land acquisition strategy for future needs

Brownfield Optimization

Transform existing facilities through strategic upgrades and expansions:

- • Capacity bottleneck analysis and solutions

- • Technology upgrade roadmaps

- • Building expansion and renovation planning

- • Infrastructure modernization priorities

- • Operational improvement opportunities

- • Phased implementation minimizing disruption

Master Plan Deliverables

- • Executive summary with strategic recommendations

- • Phased site development drawings

- • Capacity expansion timelines and triggers

- • Technology evolution considerations

- • Infrastructure investment sequencing

- • Preliminary cost estimates by phase

- • Risk assessment for long-term scenarios

- • Sustainability and energy planning

Specialized Design Expertise

Halal Processing Integration

Facility designs that seamlessly integrate Zabiha halal requirements with modern processing technology, ensuring religious compliance without sacrificing efficiency or throughput.

Multi-Species Flexibility

Design facilities capable of processing multiple species (beef, lamb, goat) with appropriate segregation, cleaning protocols, and equipment configurations for market flexibility.

Energy Optimization

Incorporate energy-efficient refrigeration, heat recovery, renewable energy options, and smart building systems to minimize operating costs and environmental impact.

Automation Readiness

Design infrastructure and layouts that accommodate current manual operations while enabling future automation adoption as technology matures and labor dynamics change.

Export Compliance

Ensure facility designs meet requirements for target export markets including EU, China, Middle East, and others, with appropriate segregation and documentation systems.

The Importance of Mass Balance

Mass balance calculations form the quantitative foundation of conceptual design, ensuring every aspect of the facility is properly sized and integrated. Our rigorous approach to mass balance provides:

Accurate Equipment Sizing

- •Processing equipment matched to throughput requirements

- •Refrigeration systems sized for heat loads

- •Storage capacity aligned with production schedules

- •Utility systems designed for peak demands

Operational Planning

- •Labor requirements by department and shift

- •Yield projections and product costing

- •Waste stream quantification and management

- •Quality control sampling requirements

Our mass balance models account for seasonal variations, product mix changes, and yield differences between species and quality grades to ensure robust facility design.

Turn Your Vision into a Bankable Plan

Start your project on solid ground with conceptual design and master planning that aligns stakeholders, validates feasibility, and creates a clear path to success.